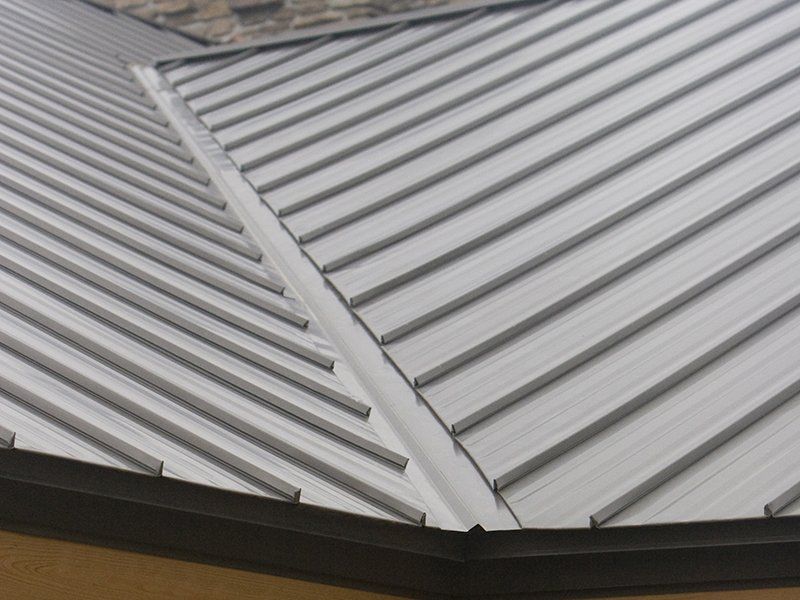

What makes up a quality metal panel?

Learn what makes up a quality metal panel.

Metal roof is produced from various firmness grades.

Making trim from Grade 80, nonetheless, will certainly cause little fractures in the metal, revealing it to rain and also eventually corrosion. Since trim has great deals of sharp bends, it is much better to make use of a softer steel such as Grade 50 or 33.

Lots of suppliers may only carry one grade of steel. This leads to either making panels out of soft steel that will certainly dent, or cut out of tough steel that will fracture. Make certain and ask your provider concerning the solidity of their metal.

Painted Galvalume ® panels provide more lasting defense over galvanized.

Some suppliers use a rust-blocking finishing called Galvalume, which blends light weight aluminum and zinc. The light weight aluminum will certainly stop any type of rust that may happen in the zinc, and also the steel will stay undamaged. The higher the number, the thicker the layer of aluminum/zinc that will secure your metal.

Should you choose Galvalume, selecting the highest thickness of aluminum/zinc will provide best corrosion protection.

Corrosion stopping is balance of substratum coating type as well as thickness.

Makers use one of two different rust-blocking coverings on metal panels, galvanized or Galvalume ®. Your metal panels will have one of these 2 coatings used in between the steel core and also the paint layer. If the paint is scraped, the rust-blocking coating is there to keep rust from reaching the steel core. Your 40-year guarantee refers to paint. Makers could include a different substratum guarantee depending on the rust-blocking finishing you pick. Ask the provider if your quote includes a different warranty for the substratum finish.

Suppliers provide panels that look the exact same, but can differ commonly in finish quality as well as performance. To help you make an educated choice you need to recognize these certain layers: the paint layer, the anti-rust layer, and the steel core.

Use this knowledge in making an enlightened choice concerning your next metal acquisition. Ask your present metal distributor to discuss the layers of defense that are included in their quote.

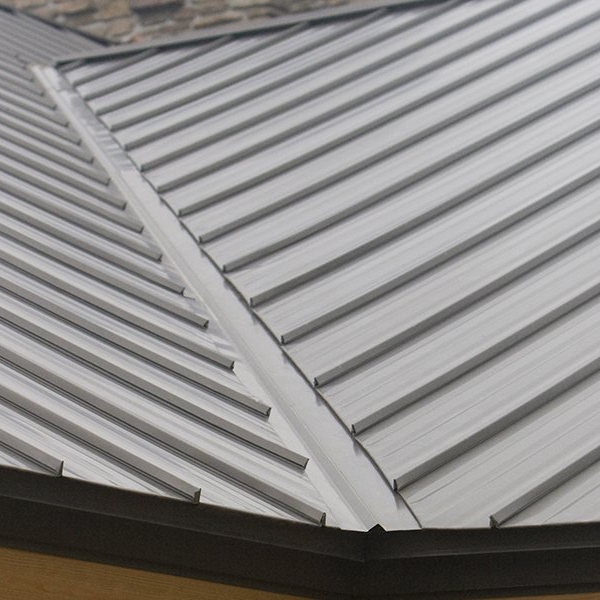

Dent resistance is an combination of steel density as well as firmness.

Focus on damage resistance as opposed to gauge. A 29 gauge metal roof comes in a wide variety of density and also solidity levels. That's not a typo. You actually could purchase a thinner 29 gauge metal roof covering or a thicker 29 gauge metal roofing system. There's not a big distinction in cost for the much better product, but you'll most definitely see a large difference in efficiency in hail and also various other damages. By understanding damage security, you could considerably improve your roof without much impact to your pocketbook. Simply requesting a specific gauge is not enough.

Painted galvanized panels reveal little edge-rust for the first 10 years.

Galvanized finishings are the standard corrosion prevention approach used in the metal market. This layer makes use of rust-inhibiting zinc, which safeguards the steel core from corrosion at the panel's edges and any surface area fractures or scrapes. The thicker the layer of zinc, the longer you have before it corrodes away and reveals the steel substrate. Galvanized is used in three usual degrees of security: G40, G60, and also G90. The higher the number, the thicker the layer of zinc that will protect your metal. Select the thickest covering of zinc for the most corrosion blocking when choosing a galvanized panel.

In the metal market, scale is an array of densities that manufacturers need to remain within. With profitability impacting prices, several suppliers are offering the thinnest metal that is allowed within the scale. It is important that you understand the thickness of your metal so you can make a informed decision.

There can be a 40% difference in damage protection between the reduced and high end of 29 gauge. When investing in a metal roof covering, this distinction in damage protection is a crucial factor to consider.

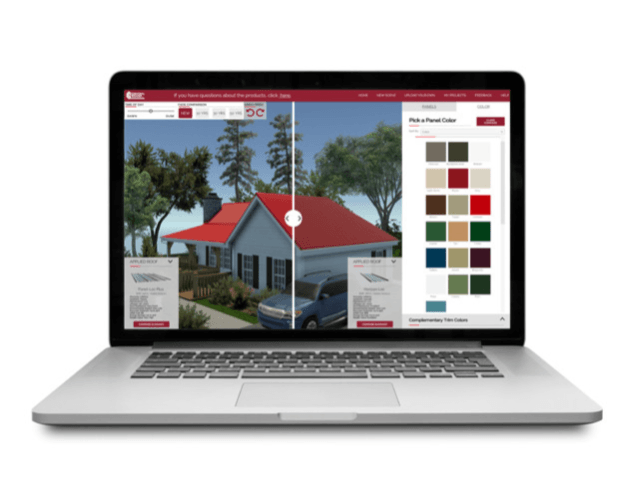

The paint system you select influences fade performance.

Some metal panels have a slim layer of paint, however supply the same warranty. The market offers metal panels with 40-year service warranties at a broad range of prices. Ask the maker for their paint density on the panels you are considering buying.You may discover that the metal you were quoted attributes a thinner, less costly layer of paint.

Some metal panels have a slim coat of paint, yet use the exact same guarantee. The marketplace provides metal panels with 40-year warranties at a vast variety of prices. Ask the supplier for their paint thickness on the panels you are taking into consideration buying.You may find that the metal you were quoted specifies a thinner, cheaper coat of paint.

We’re located at:

23320 Highway 96

Oronogo, MO 64855

Or, feel free to give us a call at 417-673-7077 to start the conversation now. You can also send us any questions you might have by email at invoices@4wmetal.com, or feel free to leave a comment below.